| B&B's Lapping Department |

|

We developed a proprietary concave-convex lapping system to accurately match component surfaces to achieve a true hydraulic float. |

|

We use optical flat light bands to measure our lapping surface to 11.6 millionths of an inch in a controlled environment Lapping Facility. |

|

Our lapping procedure is very precise and in an environmentally controlled room. The room is kept at 70º degrees Fahrenheit with a charcoal filtration to keep the finest dust particles out and off the lapping tables along with the inspection table. We use 5 micron powder to machine port plates, barrels, thrust, retaining rings, and cast iron housing. All parts are checked using optical flats that use reflective light bands measuring in the millionths of an inch. All parts that are able to be lapped are done so to keep quality at the best. |

|

|

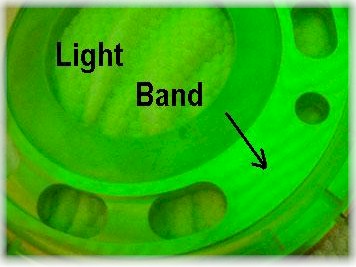

Light Band Description

The optical flat that we use is a piece of polished quarts that varies in thickness and diameter (looks like a piece of flat glass). The use of a green light is used to pass the light through the optical flat as it rests on top of the lapped work. The work piece is polished so that the surface is brought to the level of reflection needed for the light to reflect of the work. The light bands are separated 11.6 millionths of an inch and the different distortions tell if the work is concave or convex, etc. |

|

|

|

|

|

LIGHT BAND |

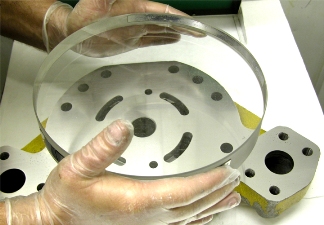

OPTICAL FLAT |

OPTICAL FLAT ON WORK |

|

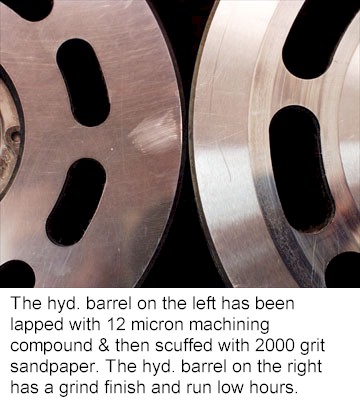

DIFFERENCE BETWEEN GRIND FINISH & LAPPED FINISH |

|

|